24??media Things To Know Before You Buy

Table of ContentsGetting The 24??media To WorkThe 6-Second Trick For 24??mediaSee This Report on 24??mediaThe Facts About 24??media RevealedThe Main Principles Of 24??media

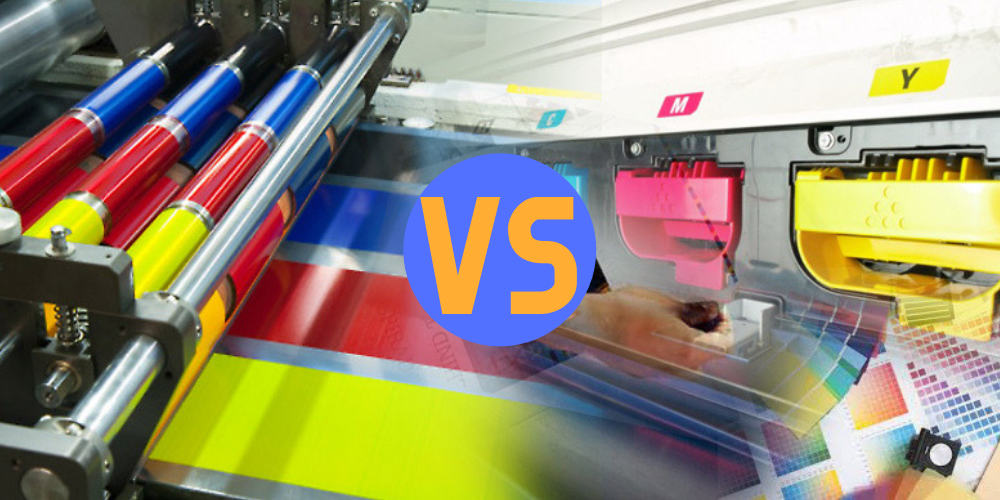

Innovations in print innovation are transforming the interactions playing field when it pertains to high quality, affordability and cutting-edge capabilities. Countered printing and digital printing are the significant processes through which print tasks are carried out both utilizing four-color printing techniques. Each choice has its benefits, supplying various strategies to satisfy the demands of diverse manufacturing jobs.

Normally, this has actually been one of the most constant method for exactly keeping color matches, making it optimal for print runs that only require fixed printing such as pre-printed forms, sales brochures, flyers, calling card, and bulk postcard mailings. Due to the static nature of litho printing, it is not optimal for variable print items that will be mailed to specific recipients such as declarations, letters, and personalized postcards.

The 7-Minute Rule for 24??media

The most current improvements in print technology are helping to bring numerous of countered's benefits right into the digital printing globe truly transforming the face of contemporary printing! There are some essential differences between Offset Printing and Digital Printing.

Today's electronic print equipment is amongst one of the most cutting-edge on the market. Right here are a few of the greatest benefits of using digital printing: dominate the digital print space, with full-color printing completed in one procedure and perfectly printed straight from a print file. Without an extensive set up procedure, the calibration time of a specific work is reduced, contributing to quicker print time and general shipment.

The inkjet printing process has actually assisted to change the sector along with the top quality and speed of the result. The most up to date inkjet technology can print on traditional countered stocks with boring, silk, and glossy surfaces. Top notch electronic print paired with software-managed color management techniques includes optimum worth to print items and makes production procedures a lot more reputable than balanced out.

Some Known Details About 24??media

(https://zenwriting.net/za24media/digital-printing-crafting-experiences-not-just-products)

Eco-friendly and biodegradable inks and printer toners are also available for more lasting printing. Digital print also gets rid of the need to clean plates or coverings with dangerous chemicals at the end of the printing process.

Variable information aids organizations reach their specific consumers and target market with uniquely-created and personalized material. As innovation boosts, the high quality of digital printing has actually come to be second-to-none, with greater detail, color match abilities and overall precision. Without the demand to clean plates or utilize excess ink, electronic printing is also much less wasteful and normally a lot more eco-friendly.

("flexo"), entail several make-ready steps to move an original image to a substratum.

The Definitive Guide to 24??media

While digital printing is a practical choice for the majority of short-run print jobsunique celebrations, prototyping, or other considerationsits modern capabilities really reveal in fast turn-arounds. Having the ability to tailor packaging with click now variable data printing has actually opened up new possibilities for you to engage with your consumers in even more personalized means. Digital printing, with less relocating pieces, is a lot more nimble than balanced out hereof.

Decreased set-up time conserves cash on the front end. And because these are not large mass orders, smaller services can afford to print without having to satisfy the higher and more expensive print thresholds of traditional printing.

Make sure you collaborate with a printing and packaging partner that has the right certifications. While eleventh-hour printing and personalization are a substantial advantage, digital might not always be the most effective approach for you. For example, counter printing has the benefit of cost-effectiveness with big print runs, particularly those with advanced attractive impacts and specialized coverings.

Excitement About 24??media

The positive plate, with its smooth surface area, draws in oil-based inks and drives away water. In comparison, the unfavorable plate, with its rough texture, absorbs water and drives away oil. Rubber rollers are after that used to move the picture from the plate to the corrugated surface area.

Corrugated paper can often prove to be a challenging surface area to publish on, but Litho prints to a separate surface area and is after that laminated to it, making it easy to publish high-quality photos. It can be extremely constant, even for futures. The a lot more you print, the less costly the costs end up being for Litho.

What Litho does not offer you is precisely what Digital does, personalization. Pricey established up Longer turn-around No Variable Data Printing Smaller shade gamut, colors can be less bright Digital printing is the process of printing digital pictures directly onto the corrugated substrate using a single-pass, direct-to-corrugate method.